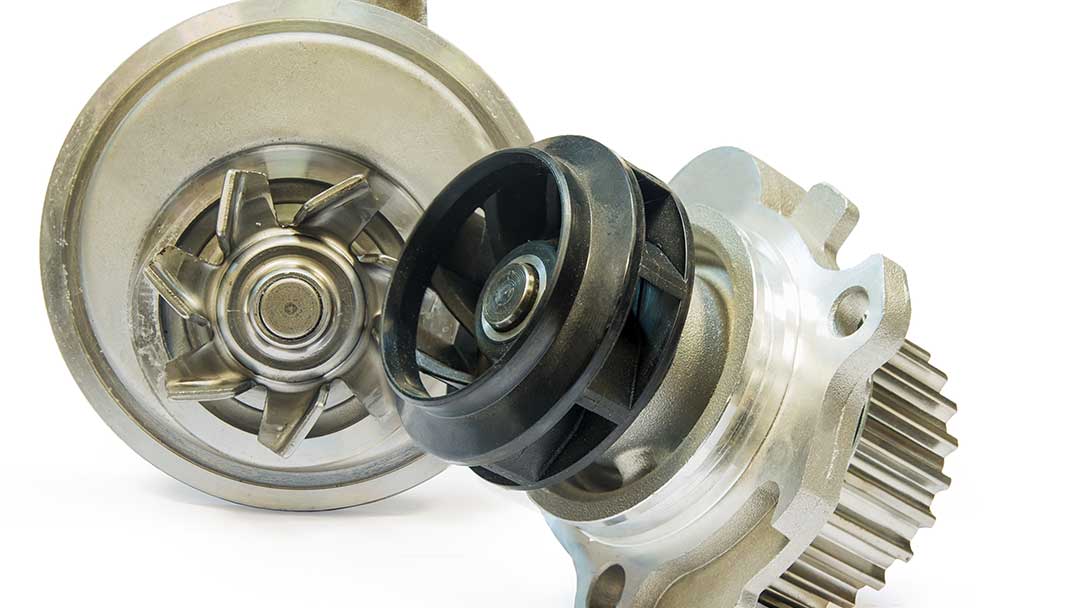

Mechanical Pumps

Mechanical water pumps have always been the go-to medium for cooling an automotive engine. The coolant flow varies with the vehicle RPM, and with that in mind, the manufacturer of the pump has designed the pump’s impeller so that it will offer sufficient flow at an idle.

The main concern for some people is the amount of drag created by the pump. Drag translates into horsepower required to operate the pump and the resulting decrease in fuel economy or performance.

Engine-driven water pumps are simple and reliable. When used on rear-wheel drive vehicles, conventional water pumps provide the mounting point for a mechanically operated cooling fan.

The longevity of both pump types is reliant on properly maintaining the cooling system and keeping it free from contamination.

Front-wheel-drive vehicles have a transverse-mounted engine (installed sideways) to accommodate the transaxle used to supply power to the front wheels.

These engines have only a few inches of clearance between the front of the engine and the vehicle’s frame. Many of the water pumps are driven by the timing belt and located under the timing belt cover.

Electric Water Pumps

Electric water pumps are offered for street use with coolant flow rates from 20 GPM to 35 GPM. When used for engine cooling only, they have the ability to perform well, especially at idle RPM.

These pumps can only be used on conventional rear-wheel drive vehicles and also require a complex wiring circuit used to activate and deactivate the pump at the appropriate times. They are offered in a block-mounted version or as a remote version, used to supply water to the heater core.

The electric water pump draws less horsepower through the increased drag on the alternator than the conventional water pump does through the engine-driven belt.