It is not a secret that a well-maintained water pump helps your car as it uses less fuel, experiences minimum downtime, and requires less investment. The time you spend on pump maintenance is actually an investment for its lifetime performance. Developing a water pump maintenance checklist guarantees the optimal performance of your car or truck.

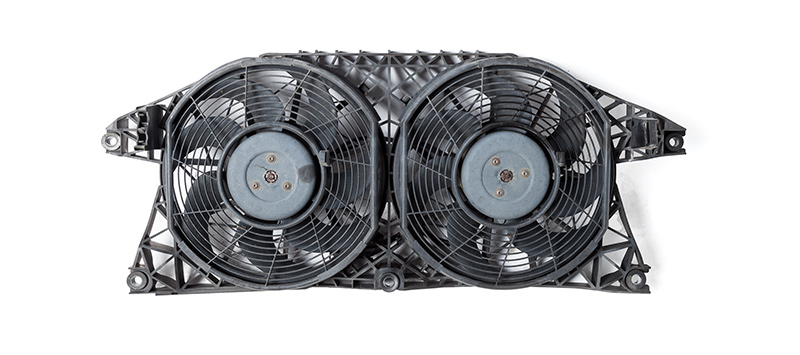

Cleaning the cooling fans

If your water pump cannot cool its motor, then you may face a serious problem in the future. A few simple steps can help you to avoid the problem of overheating. The process is simple, yet often overlooked. When the pump is switched off, use a brush with soft bristles to wipe away dust and debris that may be around the cooling fan.

Daily maintenance

It is important to take note of the discharge flow on a daily basis. Is the pump taking a longer time to do the same job than usual? Or, whether the flow has become slower? If you notice any differences, examine for leakages, fissures, or wear and tear. Drips and wet patches are the most common warning signs. Sometimes, we need to focus on the minor details, as issues not attended to and fixed in a timely manner may lead to serious problems later. Daily maintenance can reduce the chances of severe damage and cut down on vehicle maintenance costs.

Spraying anti-corrosion products

To prolong the life of your pump it is very important to spray anti-corrosion liquid. The anti-corrosion sprays are inexpensive and ensure a smooth running of the pump.

Monthly maintenance

Every month you have to look at the seals, oil the bearings, ensure that the water pump is placed firmly above the base, and change the motor couplings for adept output or transfer. These measures ensure that the water pump runs smoothly without any noise or damage. However, when lubricating the bearings follow the manufacturer’s guidelines precisely. Most of the bearing damages occur due to over-greasing.

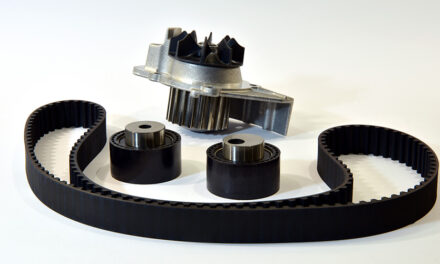

Yearly servicing

You can do daily and monthly maintenance if you have some knowledge about the water pump. You should carefully review the pump’s manual to be able to perform the maintenance job better. Alternatively, you may want to approach an automobile technician once a year. A competent professional typically inspects the pump, and repairs or replaces the bearings, drive belt, or any other parts that are malfunctioning. In addition to these, the technician will also inspect temperature and vibration to make sure that the pump is running perfectly.

Regular maintenance and inspection can save your pump from unnecessary damage and can make a big difference in extending the life of the pump. Preventive and predictive maintenance usually includes sealing the leakages, performing maintenance activities on bearings, validating motor condition, and assuring proper alignment.

However, most of the time improving the efficiency of the water pump is ignored. Improving efficiency can decrease operating costs and reduce long-term maintenance costs of your car or truck. For example, many times the speed of the water pump is tied to engine speed, as a result, it typically produces more flow and pressure during cruise speeds than needed and less during the time the engine is idling but actually needs more water. There are new technologies available that help to match the pump speed with operational needs regardless of the engine speed.